Many of you may not know this but in my early metal fabricating career I was a certified welder in the architectural metals industry. We made all sorts of custom products, using mostly non-ferrous metals such as aluminum, brass, bronze, and stainless steel. One of the many products I used to manufacture were architectural metal cladding panels. This craftsman style welding is referred to as fitting, and perhaps the most important aspect of the role, after weld integrity of course, was ensuring a flat, square, and accurate product after the welding process has cooled. This is a process that requires a skilled welder to ensure the production of a quality fabricated panel.

Why does welding aluminum cladding panels cause oil canning?

When you weld two aluminum components together, you must remember that the metal shrinks as it cools. Therefore, as the weld cools, it sucks the two components together. This can result in:

- the frames going out of square

- angles being pulled tighter than desired

- any large flat surface oil canning as the aluminum has various forces exerted on it from the heating and cooling process.

So, this brings us on to the next question…

How to do you fabricate aluminum façade panels without panel deformation and oil canning?

The answer is simple – don’t weld them! As I mentioned previously, welding cladding panels was a common thing, not only in my career, but in an entire industry but the industry has now moved on. Since then, the architectural metals industry has realized that welding panels required an unnecessary series of steps that could be easily eliminated and in the process also save and produce a superior product and finish. No more welding, grinding, and polishing, and best of all, no more oil canning!

Why do some fabricators insist that welding corners is better?

As the old saying goes, old habits die hard. While there is nothing structurally wrong with welding corners on aluminum cladding panels, it is unnecessarily costly and time consuming, and most importantly results in unsightly oil canning, grinding marks, and panel dents. Some fabricators will claim that their trained craftsmen take pride in their work and don’t have these issues. However, I was once one of these craftsmen, and our whole fabrication shop only produced the best in architectural metalwork. But as technological advancements came in and the ability to produce a better-quality product, we moved on to new fabrication processes. On another point, the welding of panels requires a skilled craftsman and these are becoming harder to find as my peers and former colleagues move on to other industries as I did or move on to retirement.

Final thoughts on welding metal cladding panels

Speaking from personal experience as a certified welder fabricating architectural cladding panels, I can say with some authority that these days cladding panels are best fabricated without welding. If you are still skeptical, below are some images showing the contrast between the two:

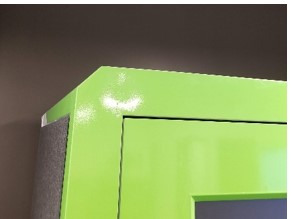

Panel deformation from welding

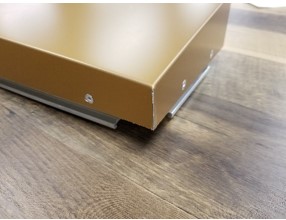

Clean crisp corner with no welding

Suggested Further Reading

If you would like to learn more about the topic of metal cladding fabrication, below are some previous blogs that we have written regarding this topic that you may find of interest:

- Should I specify an MCM manufacturer or a fabricator? – in this blog post we look at the role of current MCM fabricators who purchase flat sheets from the manufacturer and are then responsible for fabricating the metal wall panels according to the requirements of the project and what this process entails.

- How to specify Metal Panel Facades – Part III: Fabrication – this topic is part of a series of articles that we wrote regarding specifying Metal Panel Facades. This one on fabrication contains more information on the current fabrication process for MCM panels and their role in the metal cladding industry.

- 7 reasons you need to use Vitraplate aluminum cladding panels on your next project – talking about industry advancements, one of the newest products to hit the construction market is prefinished 3mm(1/8”) solid aluminum plate. Find out how this non-combustible and highly durable material could be the solution for your next exterior cladding project.

By Jerry Fossey

General Manager, Fairview Architectural