ENGINEERED TO INCREASE PRODUCTIVITY AND CAPACITY WITHOUT INCREASING OVERHEADS

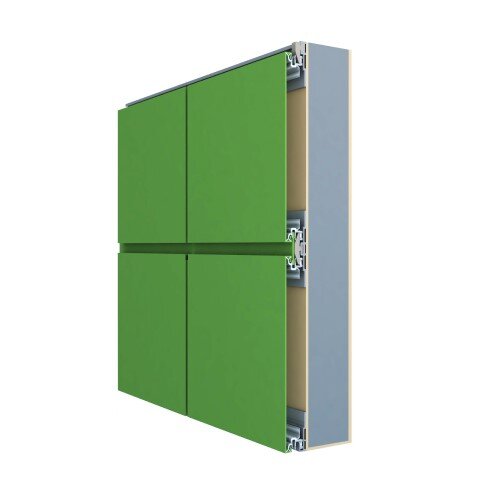

Arrowhead offers a complete facade package with a patented range of façade cladding installation systems. Our Arrowhead® systems can be used with Fairview Architectural’s Vitrabond® and Vitraplate® products and are also compatible with other brands of aluminum and metal cladding panels.

Our packages include versatile facade materials, fully tested labor saving installation and an online customer training program. If you are interested in taking our training course, simply scroll down this page and complete the Arrowhead® Training Request form.

In addition, the Arrowhead® panel installation systems use a revolutionary t-clip that both fastens the panel to the wall and allows it to be easily removed without affecting the other panels around it. This makes the Arrowhead® systems fully non-sequential.

Our Systems

Benefits:

- Aesthetically similar to traditional rain screen systems

- Designed to significantly reduce installation and labor costs.

- The base wall extrusions are shimmed and attached to the exterior wall first.

- The extrusions are then used to take the measurements for the panels.

- This allows for panels to be placed straight onto the extrusion and held in place by the T-clips.

Benefits:

- This system takes all the benefits of the more traditional Arrowhead® FLEX system and combines them with an extremely simplified fabrication process.

- No rivets are used to hold the panels to the frame, instead a double grove and slot method is used to secure the frame extrusion.

- This increases production speed due to there being less steps.

Benefits:

- As with our LEAN and FLEX systems, the FLUSH is also a non-progressive system but features a unique aesthetic feature.

- This system provides a minimalistic look with shallow reveals and is easy to fabricate.

- Arrowhead® FLUSH offers a clean esthetic for a truly modern finish to your building facade.

Key Benefits

Revolutionary

Cost cutting

Time saving

Non-sequential

Quick lead times

Our Arrowhead range is in stock at our warehouse in Connecticut and available for immediate delivery to anywhere in North America or Canada.

Easy to install

Replacing panels

Versatile

Compatible

Arrowhead Systems are compatible with our ACM / MCM Products: Vitrabond® and Vitraplate® as well as other industry brands.

Videos

Submittal Documents

If you require Arrowhead Submittal Documents, please contact us at helpdesk@fairview-na.com.

Featured Projects

Digital Architectural Binder

We offer an online Architectural Binder that provides more information on our products and systems. Choose the Arrowhead panel installation system to view the CAD files in a full range of formats. You will also find specification documents for each of our systems and other useful information.

If you are unable to find the information that you are looking for, please contact us directly.

Visit CADdetails to view Fairview’s Digital Architectural Microsite

Patents

Patent Number: 10,017,947

Patent Number: 10,208,484

Patent Number: 10, 087,639

Patent Number: 9,777,486

Patent Number: 9,903,123

Patent Number: 10,180,004

Multiple U.S. Patents Pending

Canadian patents Pending

Australian Patents Pending

United Arab Emirates Patents Pending

European Union Patents Pending