Cladding Safety with Metal Composite Material (MCM) and NFPA 285-19

One of the most talked about points when specifying MCM panels, is NPFA 285 compliance. Fire safety standards are a big concern globally, and understandably so.

Since the 1980s, innovative exterior wall systems have been developed to enhance a buildings appearance, and to improve the overall performance of a facade. Over the last decade several high-rise building fires including structures in Dubai, Shanghai, Atlantic City, and the much-publicized Grenfell Tower in 2017 has raised concerns over buildings and façade cladding safety.

The NFPA (National Fire Protection Association) has developed research and resources to help building owners and global enforcement authorities, assess the fire risk of existing high-rise building portfolios, as well as identify what fire testing procedures should be applied when designing new buildings. It has been suggested that the absence of severe apartment building fires in the U.S. is a testament to the American Building Code and additional standards such as NFPA 285.

What is NFPA 285?

The NFPA 285 test evolved from previous building and fire codes and first came into existence in 1998. The Code was updated in 2018 following the Grenfell Tower fire and has been continually revised, and improved to ensure the safety of buildings and their residents. NFPA 285 -19 (2019) is the current test standard.

What does the NFPA 285 involve?

The NFPA 285 test is classified as the ‘Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components’. This standard provides a test method for determining the fire propagation characteristics of exterior wall assemblies that are constructed using combustible materials or that incorporate combustible components.

The actual test itself is performed as an assembly test for exterior walls that contain combustible components or materials. The test determines vertical and horizontal flame spread by simulating an interior flashover fire that impacts the exterior cladding through a compromised window opening. It is important to stress the fact that NFPA 285 is a large-scale assembly test. This means that individual products and systems cannot pass the test alone. Materials are only considered acceptable when evaluated in conjunction with and as part of the entire wall assembly.

An example of a typical NFPA 285 compliant MCM wall assembly includes the following components that are often sourced from multiple manufacturers: insulation, exterior cladding panel, air barrier, water-resistive barrier, fasteners, lintels and furring.

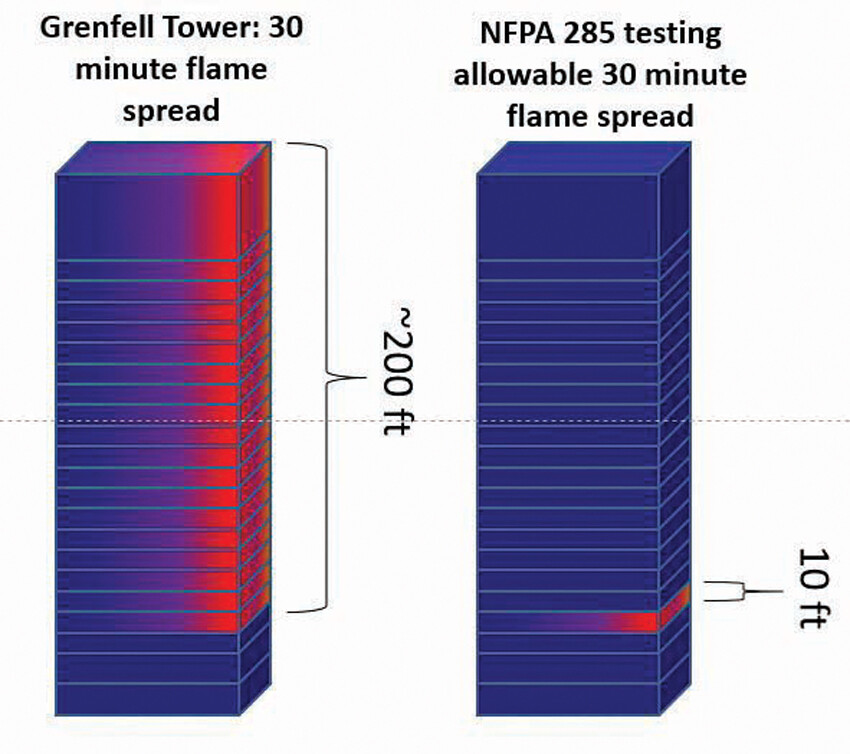

The fire exposure duration for NFPA 285 is 30 minutes. See example diagram below:

Image: courtesy of the Metal Construction Association

When is NFPA 285 compliance required?

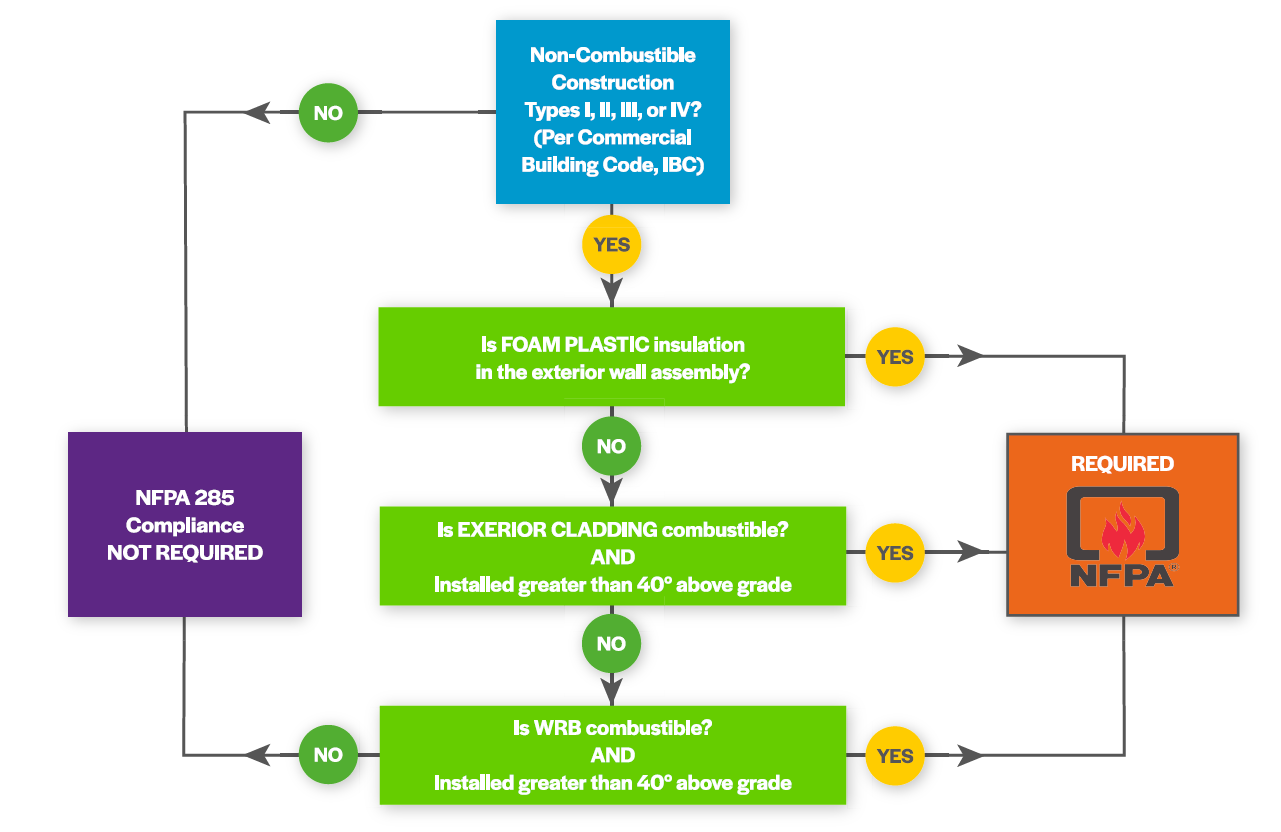

NFPA 285 compliance is required for an exterior wall assembly containing MCM panels as follows:

- Installations on buildings of Type I, II, III or IV construction that are greater than 40 feet in height where the fire-separation distance exceeds 5 feet.

- Installations of up to 50 feet if the MCM has a limited self-ignition temperature.

- Installations up to 75 feet (or beyond if sprinkler protected).

The graphic below provides a visual reference on when and where the Code is required:

Note: There are situations where a combustible Water Resistant Barrier can be used without being tested such as when the only combustible component in the wall assembly is covered with brick, stucco, concrete and a few other materials or meets certain technical parameters.

How does MCM perform against NFPA 285?

Although continually faced with updated test protocols for fire protection, metal composite material cladding is passing the test. With its Fire Retardant (FR) mineral core, MCMs perform well when subjected to NFPA’s stringent testing procedures.

Note: not all manufacturers have tested their products against the current standard, so it is important to make sure that the MCM you are specifying is compliant and accompanied by an ISO/IEC 17065 accredited report.

When exposed to fire, the metal skins of the MCM initially deflect the heat and fire away from the core material. While the metal skins will eventually melt, the material remains in place, and the metal limits both the amount of combustible core available to the fire and the spread of flame.

Also, of note is the fact that wall cavity heat gain is not typically an issue in MCM systems in the absence of exterior flames. In other words, the wall does not self-sustain once the flame source is eliminated. This is also a benefit of the FR core as it has shown to self-extinguish almost immediately.

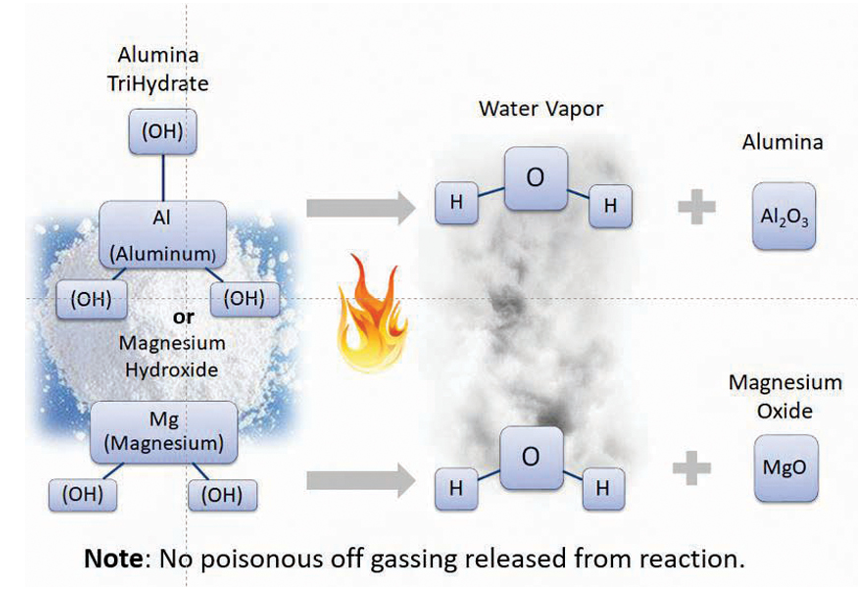

This is due to the FR core utilizing the addition of minerals, such as alumina trihydrate or magnesium oxide, that effectively break down when subjected to extreme heat. This then releases water vapor, helps suppress the fire, and causes the self-extinguishing process mentioned above once the flame source is removed (see diagram below).

Are there alternatives to using MCM panels?

MCM panels are a popular construction material and there are many advantages to continue using and specifying them as part of your compliant wall assembly. Alternative options to MCM are non-combustible solid metal panels or engineered metal plate, however, current supply chain issues caused by the high demand for raw aluminum materials, is seeing prices for these products reach all-time highs.

How to specify MCM compliant products

If you require a non-combustible cladding solution that is compliant to NFPA 285, MCM is the more reasonably priced option with the addition of being available in an extensive range of colors, easy to fabricate and install and long-term warranties.

At Fairview our range includes the MCM panel product, Vitrabond FR, that is fully compliant to NFPA 285 (report available on request) as well as the 3mm pre-finished solid aluminum panel (Vitraplate) and our innovative metal engineer plate product (Vitrabond G2). Contact our team for more information and to discuss your specific project needs.