SPECIAL STATEMENT REGARDING AVAILABILITY OF VITRABONDG2®

True to our Mission, Fairview Architectural has been investing heavily into product development in response to market demands. VitrabondG2® has now been replaced with our Vitraplate® 3mm (1/8”) Pre-Finished Aluminum Cladding material.

VitrabondG2® was introduced to the façade cladding industry in North America at the request of leading architects, specifiers and façade consultants to fill the demand for a non-combustible lightweight cladding material. At the time, pre-finished solid 3mm (1/8”) aluminum was not possible, requiring panels to be spray-painted after fabrication.

Vitraplate® 3mm (1/8”) is a foldable pre-finished solid aluminum cladding material, which can be fabricated just like VitrabondFR® MCM. By using pre-finished aluminum instead of spray-painting or post-painting, many more finishes can be achieved, with a higher quality and longer warranty. Our capabilities have been expanded and lead times reduced since we began manufacturing Vitraplate® in USA in 2023.

Fairview Architectural now offers two fully tested and compliant wall assemblies. These engineered wall assemblies can be specified as a complete package, and Fairview can supply all the components to ensure full compatibility and traceability.

LIGHTWEIGHT METAL COMPOSITE MATERIAL (MCM) MANUFACTURED IN A CONTINUOUS COIL PROCESS

Vitrabond G2 is the lightest weight product in its class. This innovative sheet product is available in an extensive range of surfaces and finishes.

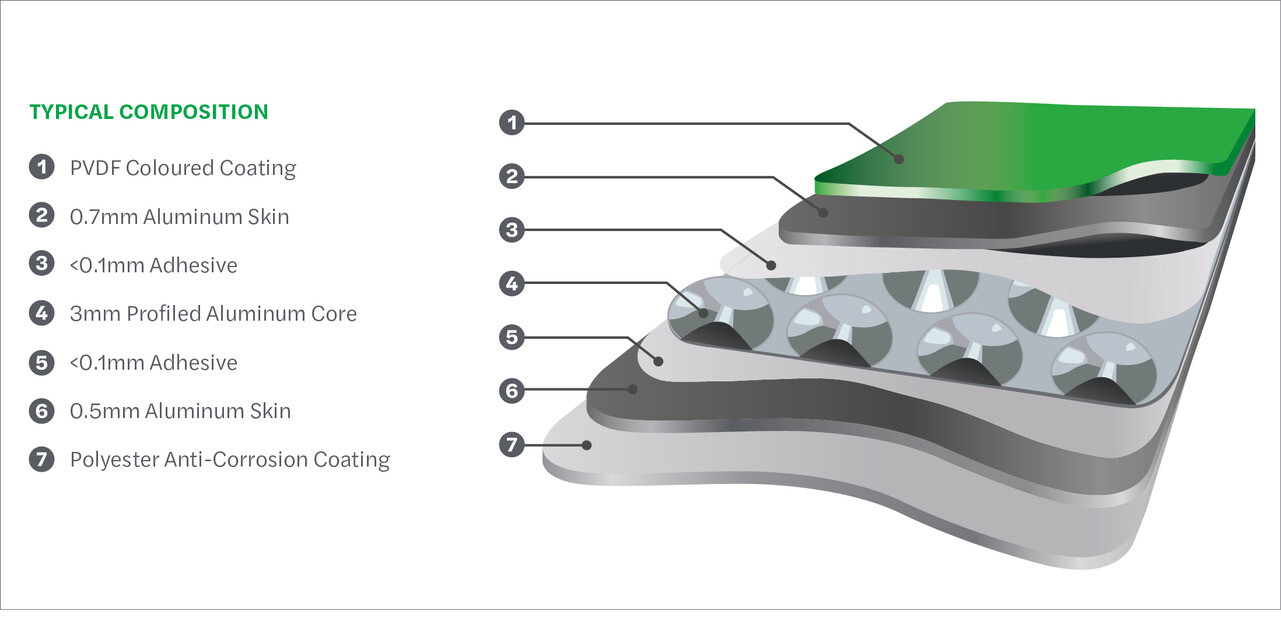

Vitrabond G2 is visually the same as a traditional metal composite material. However, what makes it different is the technology of the core which is constructed from a non-combustible profiled aluminum structure rather than combustible material.

The technology of the core allows for continuous coil production, thus producing exceptional consistency as well as a cost-effective product. Vitrabond G2 is a high-performance cladding panel that is ideal for façade applications as well as for interior applications.

Additional benefits of Vitrabond G2 include its high mechanical properties and simple fabrication. The outstanding surface flatness is enhanced by a high-quality PVDF coating system.

FAQs

Does VitrabondG2® need to be tested to NFPA285?

The short answer is “not yet”. The NFPA285 is a full-scale fire test for wall assemblies containing combustible materials. The purpose of the NFPA285 is to allow combustible components to be used, as long as the combination of components in the wall assembly does not propagate a fire. According to the International Building Code (IBC) at the time of writing this, VitrabondG2 is a non-combustible building product. The coating and bonding layers are classified as “minor combustible components”, and therefore if there are no combustible components in the wall assembly there is no need to test. Simply put, why fire test a wall assembly that is made up of non-combustible products?

Changes to the IBC are coming however that will require wall assemblies containing non-combustible products such as VitrabondG2® and mineral wool to be tested to NFPA285. This change is to close any loopholes which might allow products such as honeycomb panels, which are embedded in highly flammable glues, to call themselves “non-combustible”. So, while it might seem unnecessary for non-combustible products such as VitrabondG2® and mineral wool insulation to have to be tested to NFPA285, it is a worthwhile preventative measure to ensure our buildings in USA are built safely.

Until these changes take effect, if a wall assembly needs to be tested to NFPA285 then we recommend using our VitrabondFR, a fire-resistant product for use in combustible wall assemblies that must be tested to NFPA285. VitrabondG2® is a state-of-the-art technology advancement on painted aluminum and as such is not intended to replace standard aluminum composite material where fire-resistant products are acceptable for use.

Can VitrabondG2® be tested to ASTM E-136 to prove it is non-combustible?

The building code has two types of materials.

- Elementary materials

- Composites

A piece of aluminum is an elementary material and can therefore go through the ASTM E-136 test. If, however, you apply a coating of paint onto the aluminum, it can no longer be put into the furnace, because it is now considered a composite. To overcome this, the building code makes allowance for these minor combustible components that make up a small portion of the end product. If you ask a lab to test aluminum with paint on it, they will only test it if you sign a waiver that includes the cost of repairing their furnace. The paint is flammable, the test will fail, and the furnace will need to be repaired. So even painted solid aluminum cladding cannot be tested for non-combustibility. Instead, the aluminum itself as the primary element must be tested, and together with the minor combustible components such as paint and bonding layers it makes up a composite. Thick layers of glue as found in honeycomb panels cannot and should not be considered minor. And in case you hadn’t realized by now, VitrabondG2® is not a honeycomb panel.

Key Benefits

Low maintenance

Vitrabond G2 panels are simple to maintain. An annual cleaning regime with soapy water or pressure hose is recommended.

East to fabricate

As with our other MCM panels, Vitrabond G2 can be machine cut, routed, roll-bended, folded, and perforated without any loss of structural integrity.

Durable and lightweight

Vitrabond G2 panels are compatible with our purpose-built Arrowhead Installation Systems.