The aluminum cladding market has for many years been dominated by aluminum composite panels. A favorite with both architects, specifiers, fabricators and installers due to their almost infinite range of possible finishes, lightweight properties and ease of fabrication and installation. But the one thing they lack is the “non-combustible” label. The same, however, cannot be said of solid aluminum. We have seen a shift in specifications towards solid aluminum cladding, but is this a passing trend or something more? We explore some topics below to see who comes out on top.

Regulatory change

Building regulations are slowly changing throughout regions of North America. The changes include non-combustibility requirements for exterior cladding and further full-scale wall assembly testing on new building projects. Among the first areas jurisdictions to change their regulations are the Canadian province of Ontario, the city of Minneapolis and New York City. Although the option is to of specifying a non-combustible solid aluminum panel is now feasible, in most cases the regulations do not rule aluminum composite panels out of the mix if the wall assembly meets certain test standards.

Verdict: ACM ½ / Plate 1

Colors and finishes

Aluminum composite panels and solid aluminum panels are both able to be coil coated with the same variety of finishes and if the solid aluminum panels are pre-finished as per composite panels then the finish will perform just as well.

Verdict: ACM 1/ Plate 1

Fabrication

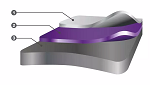

Our customers are good at providing feedback, and although the two products are similar the core of the aluminum composite panels does offer a slight advantage over the solid aluminum panels. This is because the cutters are put under more pressure when machining solid aluminum than aluminum composite, which can lead to overheating if not done correctly, causing the cutter to become dull which impacts the quality of the cut. If a fabricator cuts both composite and solid then the machine might need to be readjusted between machining each product. The ideal option is to have a separate setup for each. Both products can be machine cut, routed, roll-bended, folded, and perforated without any loss of structural integrity.

Verdict: ACM 1 / Plate ½

Ease of Installation

With a reputation for being installation-friendly, we thought aluminum composite panels would be hard to beat in this category but although lighter by approximately 40%, solid aluminum panels are not excessively heavy compared to other façade materials and are still able to be installed easily by hand.

Verdict: ACM 1/ Plate 1

Maintenance

Maintenance of composite and solid aluminum panels is another area where it is hard to split these two. With the same finish and coatings all that is required to maintain each of these products and maintain their warranty is to undertake an annual cleaning regime with soapy water or a pressure hose. It is as simple as that.

Verdict: ACM 1/ Plate 1

Final score ACM 4 ½ / Plate 4 ½

Conclusion

Having subjected these products to five key benefits that are often used to differentiate cladding products, the scores came back as tied. Therefore, the Fairview jury is out on whether solid panels such as our Vitraplate are here to stay and will end up reducing the dominance of aluminum composite panels such as our Vitrabond FR panels. We will be watching this trend with interest.

Note: we will be running a webinar on Wednesday October 21st at 3pm EST to explore this topic further including an interactive panel discussion. To join us, please register here.