In a market where brand recognition often overshadows actual performance, architects and building envelope consultants are making a decisive shift. They’re choosing materials that deliver measurable advantages, not just familiar names. Vitrabond is emerging as the preferred choice for those who demand both aesthetic excellence and proven technical superiority.

When value engineering discussions begin and fabricators propose legacy ACM brands based on name recognition alone, consider what you might be sacrificing. While established manufacturers have built reputations on being “the original” or “the industry standard,” Fairview’s Vitrabond delivers innovations that transform how façade materials perform from fabrication through decades of service life.

The Coating That Changes Everything: Vitranar® Flexible-Resin Technology

Standard ACM coatings, including those on most legacy brands, become brittle over time. The result? Micro-cracking and crazing at fold lines during fabrication are aesthetic defects that can void warranties and force costly rework.

In fact, many industry-standard warranties explicitly exclude coverage for “slight crazing or cracking as may occur on normal roll-forming or brake bending.” This means the very aesthetic defects you’re trying to avoid are written into the warranty as acceptable.

Vitrabond’s exclusive Vitranar® Flexible-Resin Coating eliminates this industry-wide limitation. Even after full cure, the coating remains elastic, completely preventing paint crazing at corners and folds. This isn’t just about aesthetics; it’s about protecting your specification integrity and ensuring warranty coverage remains intact throughout installation.

The Architect’s Advantage:

- Flawless corners on every panel, your design vision realized without the compromise other manufacturers write into their warranties

- No aesthetic callbacks during construction, eliminating the “accepted standard” defects

- Warranty protection that actually covers fabricated panels, not just raw materials

Warranty Protection Beyond Industry Standards

Read the fine print on most ACM warranties and you’ll discover limitations that significantly reduce long-term value. Many legacy manufacturers offer warranties that are non-transferable, provide limited delamination coverage, or even diminish protection on replacement panels. Vitrabond takes a fundamentally different approach:

- Up to 40-year coastal finish warranty (non-prorated)

- 20-year material warranty covering delamination (non-prorated)—double the industry-standard 10-year coverage

- Transferable to subsequent building owners—unlike non-transferable warranties that terminate upon sale

- Repair-and-replace coverage, not just material credits

- New warranty periods for replacement panels—versus warranties that only cover “the remainder of the original period”

For developers and building owners, this means your façade investment is truly protected for decades, not just on paper, but with real financial backing that doesn’t evaporate at sale or diminish over time. For architects, it means your reputation is safeguarded by warranty terms that withstand scrutiny.

Proprietary Thermal-Reactive Core: Fire Performance Beyond the Standard

While conventional fire-rated ACM meets NFPA 285 requirements through passive mineral-filled cores, Vitrabond’s proprietary thermal-reactive core actively responds to fire events, not just resisting flame spread, but actively managing thermal energy.

This innovative core technology features micro-particle additives engineered to absorb and dissipate heat during fire exposure. The result is superior performance that provides building occupants with critical additional protection during the most dangerous moments, going beyond what standard products deliver.

The Consultant’s Confidence:

- Performance that exceeds code minimums, not just meets them

- Active thermal management versus passive fire resistance

- Enhanced life safety beyond basic NFPA 285 compliance

Additionally, this thermal-reactive property delivers a surprising fabrication benefit: reduced heat buildup during routing. Your fabricators will experience longer cutter life and cleaner grooves, translating to better corners and reduced shop time compared to standard products.

Transparency You Can Trust: Complete Testing Documentation

In an industry where manufacturers sometimes obscure testing data or rely on generic certifications, Fairview Architectural sets a higher standard. While many competitors make documentation available “upon request” or through lengthy inquiry processes, Vitrabond provides immediate access to:

- Complete third-party test reports (AAMA 508/509, NFPA 285, ASTM E84) – immediately downloadable

- Documented QA/QC processes for every production run, not just compliance badges

- Traceable batch certifications that verify material composition

- Independent lab validation through recognized testing facilities

- Ready-to-use submittal packages versus documentation that must be assembled on request

This level of transparency isn’t just good practice; it’s essential for architects defending specifications and consultants validating system performance. When building officials or peer reviewers question material choices, Fairview’s documentation provides unambiguous answers without delays.

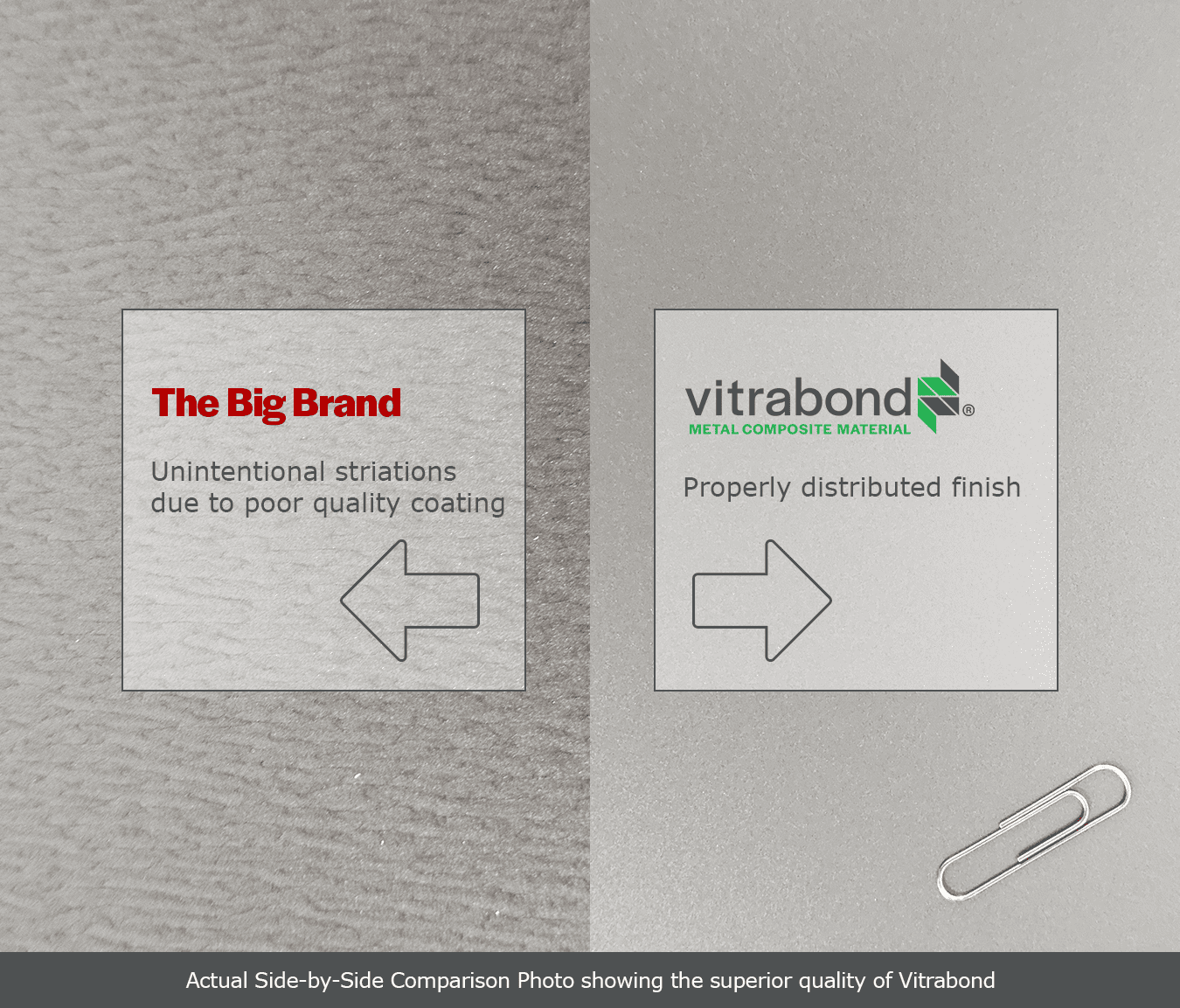

True-Flat Technology: The Foundation of Fabrication Excellence

While many manufacturers claim “superior flatness,” the reality in fabrication shops tells a different story. Inconsistent rigidity, oil-canning, and variable routing performance force fabricators to sort materials and adjust processes, wasting time and money.

Vitrabond’s proprietary True-Flat Technology delivers measurable, consistent results that fabricators depend on daily:

- Uniform rigidity across every panel, no sorting required

- Zero oil-canning or rippling—eliminating visual defects common in standard products

- Consistent routing performance throughout production runs

- Predictable behavior during forming and installation

The Fabricator’s Reality: This isn’t about marketing claims, it’s about shop efficiency. When every panel processes identically, fabricators reduce waste, minimize rework, and accelerate production. That consistency translates directly to better margins and faster project delivery.

North American Supply Reliability

Global supply chains create uncertainty. Extended lead times, variable stock availability, and unpredictable delivery schedules plague many established brands. Fairview Architectural operates differently, maintaining:

- Millions of square feet of in-stock inventory

- 2-5 business days plus shipping on stock items

- 8-12 weeks for non-stock and custom orders

- 97% on-time delivery rate verified across thousands of shipments

- Direct technical support from experts who understand North American building codes

When project schedules tighten and deadlines loom, this domestic supply capability becomes the difference between on-time completion and costly delays, regardless of how well-known the brand name might be.

The Real Question for Specifiers

When you specify materials based on brand familiarity rather than performance, who benefits? Certainly not your client. Not the building occupants. Not your professional reputation.

Vitrabond offers something better than a legacy name; it delivers measurable advantages at every stage:

- Design freedom through superior finishes that eliminate warranty-excluded crazing

- Fabrication efficiency via True-Flat Technology and thermal-reactive cores

- Installation confidence backed by immediate access to comprehensive documentation

- Lifecycle protection through transferable warranties with double the delamination coverage

- Supply reliability that keeps projects on schedule regardless of global disruptions

Before you accept a value engineering substitution based on name recognition alone, ask your team one question: Are we specifying what’s familiar, or what’s truly superior?

Review the Evidence for Your Next Project

Fairview Architectural stands ready to provide detailed comparisons, testing documentation, and project-specific support. We invite you to examine the technical differences that make Vitrabond the choice for architects and consultants who demand proof, not promises.

Contact us to discuss your specific application requirements and receive comprehensive documentation supporting your specification decision.